Introduction to Inventory Management

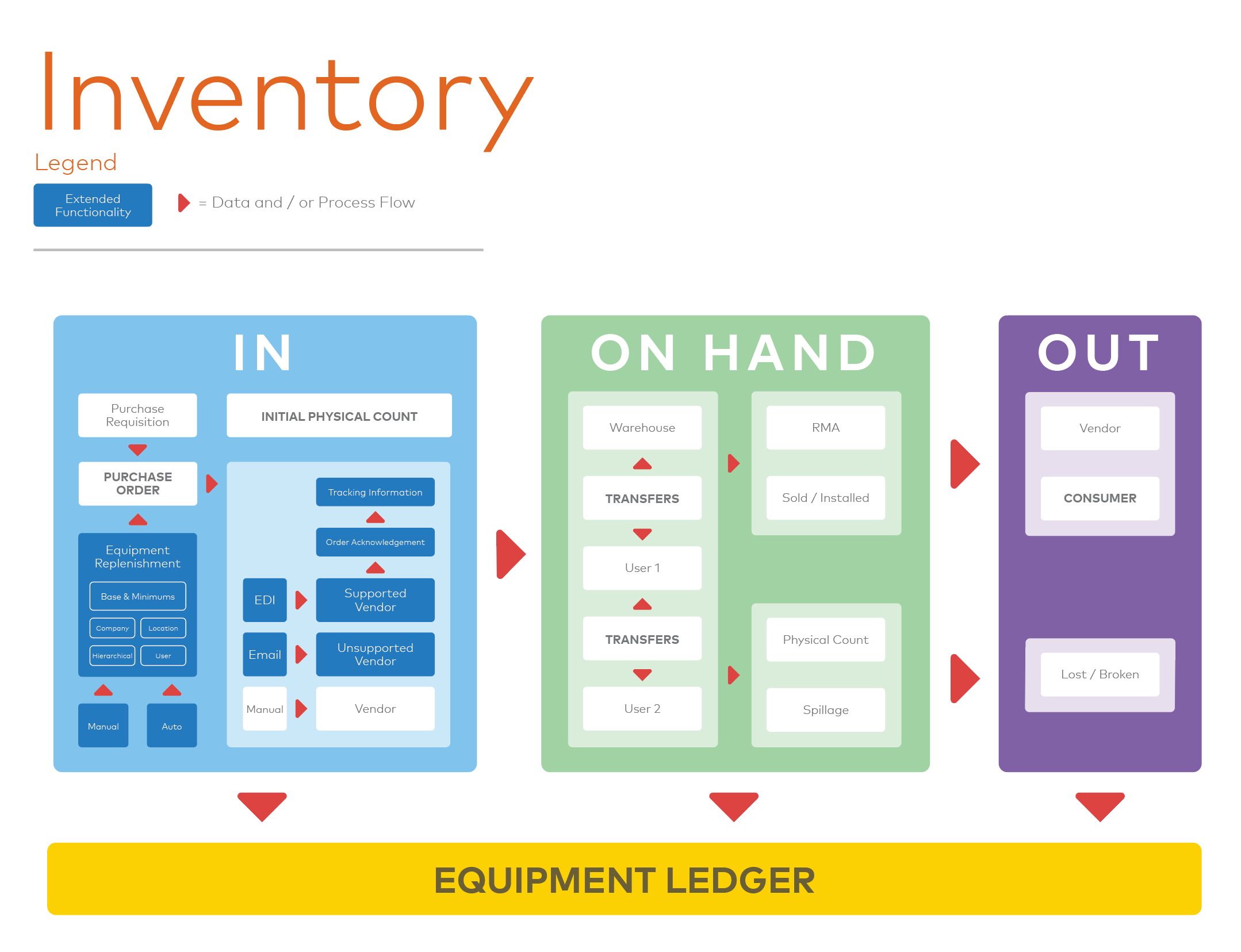

The SecurityTrax inventory system allows you to manage every aspect of your inventory to track all equipment that comes in and out of your company. This article covers concepts and capabilities and provides examples of their use.

This page includes information about features included with the Inventory+ add-on.

Terms

View the complete list of terms used in inventory management.

Equipment Item

Represents the items that your company uses in the course of business operations. Note: In SecurityTrax, this list does not contain Equipment Kits, which are treated separately.

Equipment Kit

A collection of Equipment Items that are bundled together for ease of ordering. In SecurityTrax, kits are used only for the act of purchasing and are not usable in any other way. When a kit is assigned to an Inventory Recipient, it will be broken apart and the individual Equipment Items of the kit will be assigned.

Equipment Vendor

A company that sells and distributes equipment to your company.

Inventory Ledger

An all-inclusive record of transactions related to moving of equipment to, from, and within a company. All actions in the system are tracked and reportable to ensure you have a clear understanding of all inventory-related transactions.

Inventory Recipient

An entity that participates in your inventory system that can be assigned inventory items. In SecurityTrax, users and office locations can be designated as inventory recipients.

Inventory Template

Used to specify preferred vendors and desired quantities of Equipment Items for Inventory Recipients. Includes data such as items, Default Vendor, and Minimum Level, and Base Level.

SecurityTrax Master Equipment List

SecurityTrax maintains a master equipment list that contains a comprehensive list of Equipment Items that we have identified. Your Equipment Items can be linked to our items, which will provide you with some additional features. For example, with the link in place, we will automatically group your equipment by category in equipment lists. Additionally, the link provides part-specific identification internally and externally to your company.

Spillage Report

Used as a means to remove faulty equipment from a recipient's on-hand count. Spillage Reports may also be used by a warehouse manager if a technician returns defective equipment to the office with no explanation of the defect. These reports can also be used as a precursory step to creating an RMA.

Transfer

Allows you to move Equipment Items from one Inventory Recipient to another (until the transfer has been accepted by the target recipient, no changes are made to the on-hand counts of either source or target recipient).

Setup

Before using the inventory system you will need to do some setup. Complete the following steps before proceeding:

- Add the Equipment Items and Equipment Kits you work with into your Equipment List. Make sure to link the Equipment Items to the SecurityTrax Master Equipment List.

- Add the Equipment Vendors you purchase Equipment Items and Equipment Kits from.

- Make sure to click on the Equipment Details tab to specify which Equipment Items the vendor supplies to you and related details.

- If using Inventory+ click on the Connector Details tab setup electronic communication with the vendor.

- If using Inventory+ add your Inventory Templates. This will allow the system to automatically generate POs by analyzing current and desired inventory levels of Inventory Recipients.

- Setup your users and office locations to be Inventory Recipients so they can participate in inventory management. Learn more about setting up your Inventory Recipients.

Initial Inventory Levels

After getting your system setup you will want to make the system aware of all currently on-hand inventory. You can do this now, and reconcile at any time, by having all Inventory Recipients perform a Physical Inventory count. Learn more about performing Physical Inventory.

Usage

Inventory Ledger

All inventory related activities that effect on hand counts are reflected in the Inventory Ledger. It is your source of truth to view historically what has happened and all associated details of each transaction.

IN

Equipment gets into the system in one of two ways: performing Physical Inventory, or more commonly, through the Purchase Order process.

Knowing what to order

You can determine what equipment needs to be ordered in the following ways:

- Inventory Recipients can create Purchase Requisitions indicating the equipment they need.

- When manually creating a Purchase Order for an Inventory Recipient you can see their on-hand levels and specify how many of each Equipment Item to order.

- If using Inventory+ the system will automatically determine the Equipment Items needed from the Inventory Templates through Replenishment activities.

Purchase orders

Purchase orders are the primary means by which Equipment Items make their way into your system. All purchase orders start out as Pending Purchase Orders. Pending Purchase Orders can be created in the following ways:

- Manually by clicking ADD on the Purchase Orders page.

- Automatically when converting a Purchase Requisition to a Purchase Order.

- Automatically when performing Replenishment activities.

Pending purchase orders only exist in real-time and are not saved around for later use. This is because inventory levels of Inventory Recipients is very fluid and you should always create your Purchase Orders "just in time".

Saving a Pending Purchase Order creates a non-editable Purchase Order. If using the Inventory+ add-on the saving of the Purchase Order could optionally initiated the electronic submission of the Purchase Order to the designated Equipment Vendor.

Learn more about Pending Purchase Orders.

ON HAND

Viewing

Once all recipients have performed their physical inventory counts the system will be aware of all current on-hand items per equipment item per inventory recipient. You can view these levels at any time by viewing the On Hand page and selecting the desired Inventory Recipient.

Transferring

Transferring equipment can be used to move equipment from the on-hand counts of one Inventory Recipient to another. Transfers will stay in a state of Pending until they are either Accepted or Rejected.

OUT

Inventory makes it way out of the system in the following ways:

-

Equipment in Installed - As items are marked as installed by technicians and the Install Inventory Technician is set the Equipment Items will be deducted from the Inventory Recipients' on hand counts.

-

Spillage Reports - As Inventory Recipients add items to Spillage Reports they are automatically deducting from their on hand counts. Learn more about Spillage Reports.

-

RMAs - RMAs do not effect on hand counts. They are simply used for your record keeping to indicate that you expect those items to be replaced by the Equipment Vendor. Learn more about RMAs.